Measuring up to the challenge

21 août 2017 16:16 Laisser vos pensées

This week, I had the opportunity to head out to the log yard and practice some scaling. We have scalers at Blue Ridge, who are all excellent at their jobs. It was a great opportunity to learn from one of them, and I wanted to give some insight into the world of scaling. Scaling is important to forestry because we need to have a fair and consistently applied basis for measuring the volume coming into the mill. Scaling is how we estimate the volume of the harvested timber. Scaling can be utilized for contractor payments, ensuring contractor quality, and reporting on annual crown volume.

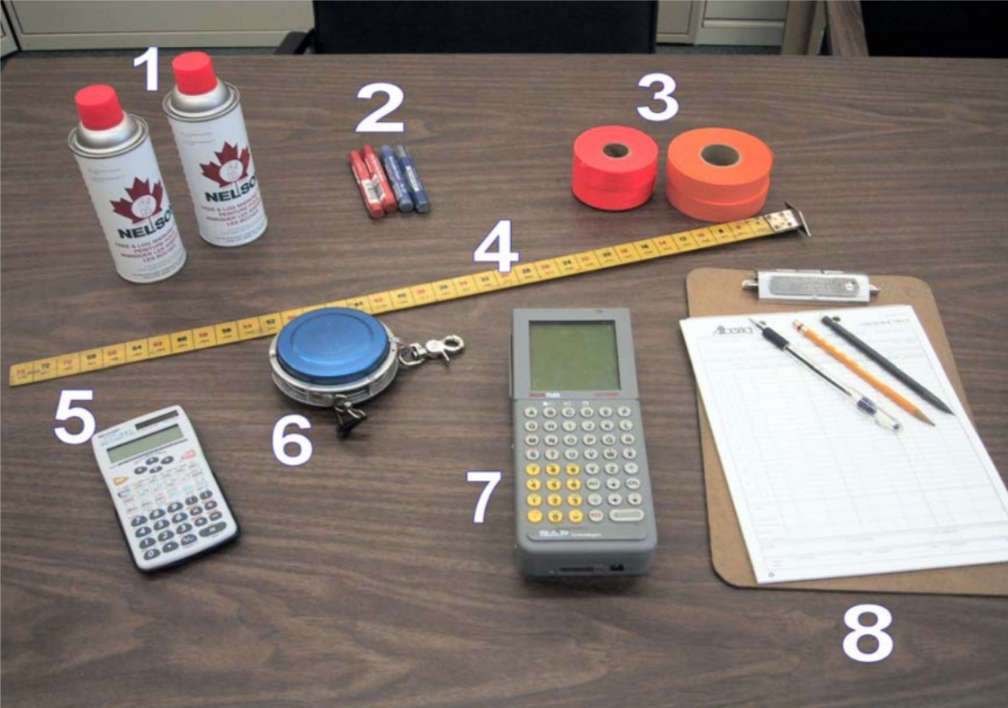

Blue Ridge will usually pull two loads (samples) per pay period per contractor. A truck coming in will be identified as a sample load and pulled off into the log yard where the logs will be placed, bucked, and then scaled. Our log yard workers will ensure that the tree length logs are bucked to specified lengths, while the cut to length logs are measured to ensure the contractors are following Blue Ridge’s specified lengths. Once the sample is ready to be scaled, our staff will take out a scale stick, handheld field computer, lumber crayon, and a measuring tape. Usually, it’s easier to scale with two people as one can take the butt size measurements and the other can take the top sizes.

For measuring the logs, each person will use the scaling stick to measure the diameter. Scaling sticks are usually fibreglass sticks marked in 2 centimetre classes. The person without the scaling computer will call out their diameter and the length of the log. The person with the computer will insert their diameter, along with their partner’s numbers, and also any defects, their deduction methods, and condition of the log. For example, if a log has a crook defect, we usually use the deduction method called percentage deduction. To calculate the percentage deduction, you divide the deflection by the diameter at the end affected, multiplied by the length affected divided by the total length, and multiply again by 100 to get a percentage. There’s quite a bit of math involved in scaling, but with the advancement of the field computer, it’s easier because most of the time you just have to insert your measurements and it calculates the math for you. There are multiple other types of defects and deduction methods, and scalers need to ensure they use the correct method and correctly identify the defect.

During my time scaling I was only allowed to help out with company loads. These loads are samples that Blue Ridge pulls out for their own sampling procedures. However, if I had a scaling ticket, I could help out with the crown loads. To obtain a scalers ticket, you must go through a week long course and pass a test. Crown loads are check scaled by a governmental official after our company scalers have worked with them. Check scaling is important because it ensures a consistent basis is being used accurately amongst all of the wood products producers in Alberta. Blue Ridge also hires a contractor to check scale some of our loads, just to ensure that we are always consistent and meeting expectations. For all the loads that aren’t pulled to be samples for our scalers, they are “weigh scaled”. These trucks will weigh themselves before entering and leaving the yard. We can compare the weight to volume of the truck, and estimate how much volume is being brought in.

I really enjoyed my time learning about scaling, and I hope to get some more experience later on! It’s a critical part to our industry!

P.S. my back has never been so sore…

Thanks for reading blog #7! Next blog I’ll be discussing the planer mill and our energy plant!

Cheers,

Gillian