Blog 7 – Jessica Rempel

September 11, 2018 2:47 pm Leave your thoughts

Okay friends, it’s time I gave you an update on all the exciting things I’ve been doing at work. Because believe me, it has been VERY exciting (at least to me).

The project that I have been working on for the past 4 months (the one I described in blog #2) is finally being rolled out into the Sawmill. A little recap on this project, we’ve been attempting to position a pneumatic cylinder using proportional pressure regulators. That may seem super nerdy to some people, but the gist of it is that we can command any position on a cylinder and it will go there. We’ve had a set-up in our office for the past 4 months in which we have tested, taken apart, retested, ordered new parts, changed our code, and tested again. Then repeated these steps over and over again at least 5 times. After all of this time we finally have it running flawlessly in our office. Literally stopping on a dime exactly where we want it to!

So this past weekend it was time to put it to the real test and install it in the sawmill. Being the naive and inexperienced person I am, I was fully under the impression that we would install this, test it once or twice, and have it working like a charm. Unfortunately that wasn’t the case even in the slightest. In our office we were testing without any mass on the cylinder, but out in the sawmill it was connected to a 400 pound press roll arm! Anyone who knows a little bit about physics would immediately realize that this large mass would produce a ridiculous amount of momentum that would need to be stopped. And so, I spent the entire weekend writing new code to try and bring this roll to a stop right when I needed it to. This proved to be quite the task indeed. Since small movements were easier to stop than the big movements, a standard set of logic wouldn’t work for all types of moves. I tried using many different techniques to stop this cylinder, and all of them proved unsuccessful. There were definitely many moments amidst this process where I thought this entire project was going to be a failure, and that we would never be able to get it to stop where we wanted it. However, my faithful supervisor reminded me several times that there were still many methods we needed to try before we gave up on it.

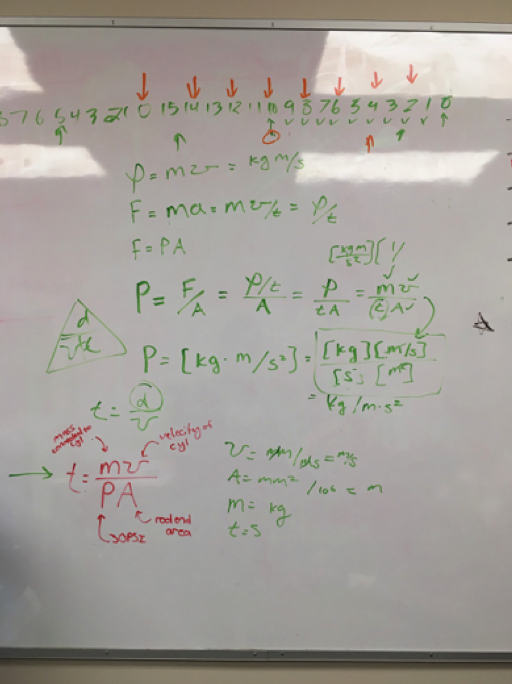

And now comes the exciting stuff…. for me at least! We decided to do a little math of our own to calculate some specifics of how the press roll was reacting to our logic. Being the math lover that I am, I pulled out my trusty calculator and got to work. Using formulas I learned in university, and writing logic with my supervisors help, I was able to calculate the exact amount of time until the cylinder would come to a stop. And by “exact”, I mean relatively close to the amount of time until it stopped. As I learned very quickly these past few weeks: you can engineer and do as much math on paper as you like, but not until you test it in the real world will you realize all of the small factors you forgot to consider. And so with this relatively close time value we adjusted our code to attempt to take into consideration the momentum of the press roll. We tested the cylinder after these adjustments and we were able to stop the cylinder exactly where we wanted it! And this time I really do mean “exactly”! The logic was working far better than I even imagined it would be able to, stopping within fractions of a mm at times!

All of this to say, that the hard work of the past 4 months has finally paid off! And it looks like I’ll have my hands full for the next 4 months as we install more of these throughout the sawmill!

Thanks for reading! And stay tuned for my final blog post in two weeks!

Jess Rempel