The Wonder from Down Under

19 juillet 2016 17:42 Laisser vos pensées

Peanut butter and chocolate. Drake and Rihanna. Canfor Pulp and Licella. Innovation happens when complimentary factors converge. That’s what Martin Pudlas, VP Operations at Canfor Pulp said at the International Bioenergy Conference & Exhibition held in Prince George earlier this month. Significantly more relevant than Drake and Rihanna, he was talking about Canfor’s joint venture with Australian biofuel production start-up Licella.

Peanut butter and chocolate. Drake and Rihanna. Canfor Pulp and Licella. Innovation happens when complimentary factors converge. That’s what Martin Pudlas, VP Operations at Canfor Pulp said at the International Bioenergy Conference & Exhibition held in Prince George earlier this month. Significantly more relevant than Drake and Rihanna, he was talking about Canfor’s joint venture with Australian biofuel production start-up Licella.

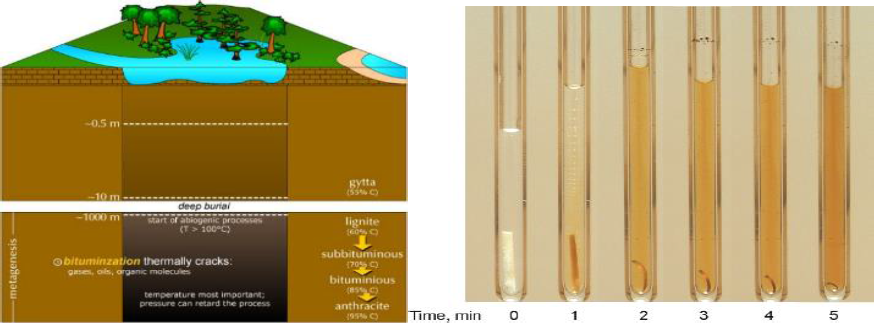

Licella is a subsidiary of Ignite Energy Resources (IER), a natural resource and energy technology development company. They have developed the patented Catalytic Hydrothermal Reactor (Cat-HTR) that converts low value biomass to valuable products. The process uses any form of lingo-cellulosic biomass feedstock to produce biocrude oil. In everyday language Licella’s Cat-HTR basically creates conditions of elevated heat and pressure similar to those needed to produce crude oil in the earth’s crust. However this is probably the only similarity Licella’s biocrude oil has to naturally occurring crude oil. Whereas crude oil is a non-renewable finite resource that takes millions of years to form, Licella’s process takes minutes. Using water at a supercritical state to pulverize the biomass, the Cat-HTR breaks down the ether linkages in the feedstock polymeric structure. By using water as a catalyst the process is not only cost-effective but also convenient, allowing for a wide variety and mixture of feedstock.

Figure 2: (Left) Natural crude oil formation can take millions of year. (Right) Licella’s Cat-HTR process takes minutes using water as a cost-effective catalyst.

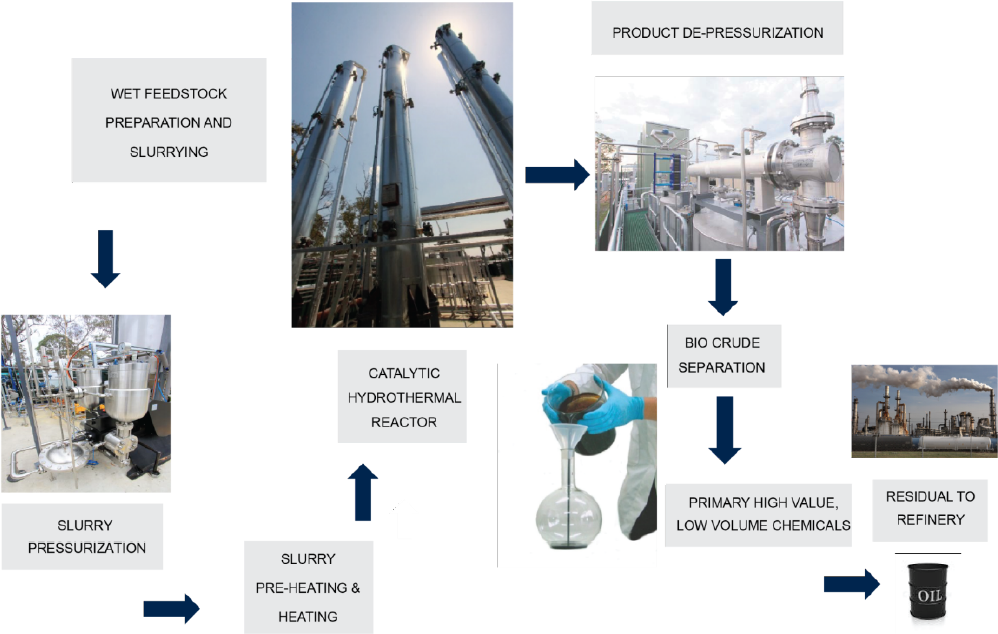

Though still in the early phases of development, the Licella Pulp Joint Venture will be the first ever commercial-scale biocrude oil plants. The project will explore the economic feasibility of converting wood waste from Canfor’s Prince George pulp mills into mass quantities of crude oil. As Mr. Pudlas stated, Licella’s technology is a natural extension of the existing pulp process. This is due to the Cat-HTR’s ability to utilize the existing infrastructure and feed streams present on-site.

Figure 3 below depicts the simplified Cat-HTR conversion process

Figure 3: Proposed bio-refinery base integrated into Canfor Pulp’s Kraft Mill in Prince George, Canada.

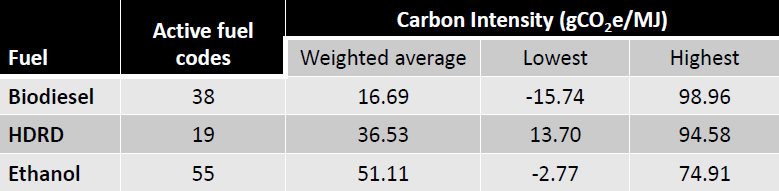

With transportation accounting for 38% of GHG emissions (Ministry of Energy and Mines, 2012), the BC government has set out additional requirements pertaining to Renewable and Low Carbon Fuel Regulations. Part of these requirements include a 5% renewable content in gasoline and a carbon intensity reduction of 10% by 2020. This has created an important “hosting condition” for the project by enabling substantial value creation for Carbon Markets. By supplying low carbon fuels, suppliers are able to receive credits. These credits can be used to offset debits associated with high carbon fuels.

According to data presented by Michael Rensing Ph.D. of BC Ministry of Energy and Mine’s Low Carbon Fuels Branch, the proposed ultra-low carbon fuel facility has the potential to avoid over 127,200 tonnes of GHG emissions per year. And to think this is all done without limiting the various ways in which British Columbians use in their vehicles is a little mind boggling.

A couple weeks ago my dad showed me a quote by R. Buckminster Fuller. It goes something like “You never change things by fighting the existing reality. To change something, build a new model that makes the existing model obsolete.” And that is exactly what Canfor and Licella seem to be doing with the Licella Pulp Joint Venture. The impending project poses an exciting and innovative economic possibility and I for one cannot wait to see the promising future of large-scale biocrude production plants.

You can find more information on the Cat-HTR at http://www.licella.com.au/cat-htr/