Let it Burn

August 22, 2016 3:15 pm Leave your thoughts

In addition to weekly effluent testing, Canfor Pulp Innovations also handle customer inquiries and complaints about its pulp products. One of our customers has been finding sand particles in their finished paper when using Canfor pulp. We suspect that this is due to the screen is not properly removing the sand and other undesirable materials at the beginning of the papermaking process. To test whether this theory is correct, pulp samples were sent to us from before and after the screening process, in addition to paper samples with Canfor Pulp. To investigate, we are going to measure the amount of silicon present in the pulp and paper using ICP-OES since sand is made from SiO2. If a large amount of silicon is present in the sample collected after screening, it will indicate that screen was not very effective and may need to be replaced.

Method:

To analyze our pulp and paper samples, they need to be ashed to burn off any organics. Once ashed, the sample is digested using nitric acid before analyzing using the ICP. A replicate sample is prepared where the acid-insoluble silicon solids are filtered and weighed.

Procedure:

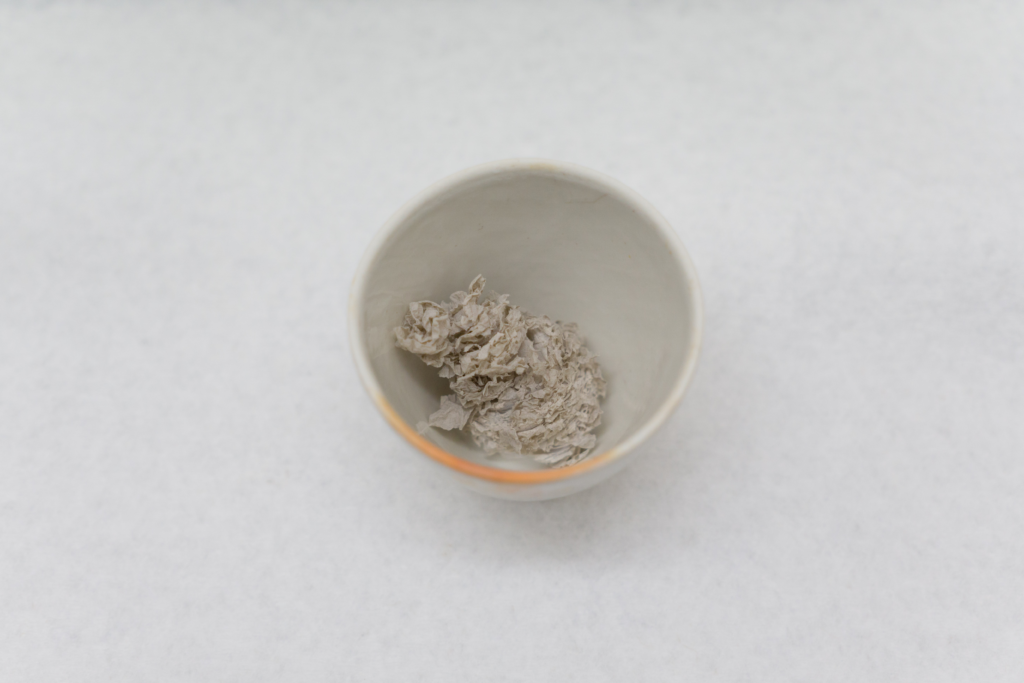

About 5 grams of paper and 10 grams of pulp are weighed out in ceramic crucibles.

Once all the samples are prepared, they are put into a muffle furnace to slowly burn off the organic compounds so that only the inorganics remain. It is important that during this step that the samples do not catch fire. To achieve this, we put a lid on the top of the crucibles to limit the available oxygen for combustion and slowly ramp up the temperature to 525°C where it ashes for several hours.

The samples remain in the furnace overnight and cooled to 250°C before they are taken out and cooled in a desiccator to room temperature.

Once ashed, the crucibles are taken to a fume hood where 5 mL of nitric acid is added to dissolve the ash.

As you can see below, not all of the ash will dissolve in the acid. The contents of each crucible is transferred to volumetric flasks and diluted before being analyzed using the ICP.

One of the replicates will be analyzed using the ICP (see previous blog post) to measure the amount of soluble silicon in acid. The other replicate will be filtered through a glass filter paper where any insoluble silicon compounds will be weighed after drying in an oven overnight. Combining both the soluble and insoluble silicon concentrations, we get the total silicon concentration and thus the total sand content of the pulp and paper.