From Logs to Lumber

June 30, 2014 10:00 am Leave your thoughts

This past two weeks I have been fairly busy. I am also starting to get more comfortable with my role and I am starting to adjust well. I get feedback from the machine monitoring and make adjustments as needed in order to keep the lumber on target size. I have also made a few work instruction manuals for other employees to trouble shoot the machinery when management or myself are not around to help.

Sawmill lesson: Here is a lesson on how lumber is made at my mill:

Part 1

Logs come in:

Cut to length: They come in on two lines

Then sorted by diameter by an operator:

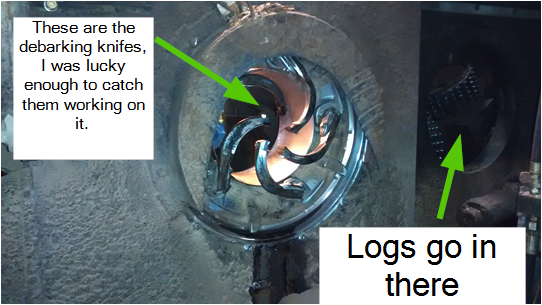

Then the logs are debarked:

Logs sorted by diameter:

These are the bins:

From the bins they get scanned:

From the scans a program decides how to turn the logs and what boards it can create from the log.

That’s it for now stay tuned for the next blog to learn more!!