It’s a myth that “The pulp and paper industry is old and has no more room for growth”

March 11, 2014 1:31 pm Leave your thoughts

I had heard that a lot at school and a lot from my parents since numerous saw mills closed in the Vancouver area back in the late 1980’s. When I came to Slave Lake Pulp (SLP), I was expecting to work mostly with pulp and other wood products that are made by West Fraser. I was surprised when I arrived to learn I would be working on a “biomethanation” project. Working at the pulp mill has changed my perceptions of what the forest industry is like today. In reality, the forestry industry is growing and is constantly upgrading.

A new generator arrives at the mill

So what’s new at Slave Lake Pulp and what are we doing to move forward in environmental activities and clean energy generation?

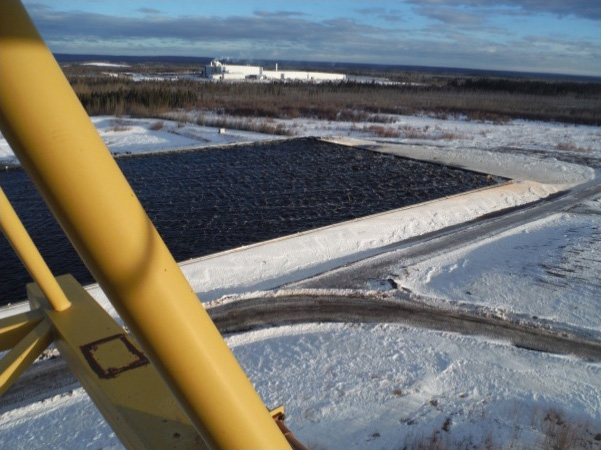

Alberta organizations such as the Climate Change and Emissions Management Corporation (CCEMC) provide funding for projects that reduce greenhouse gas emissions that are “new and novel” – meaning that the project is original and innovative to the industry. At Slave Lake Pulp, a 120,000 cubic meter tank was built last year to serve as anaerobic fermenter which will take waste water from the mill and digest it into methane gas. The gas will be cleaned and then burned in the engine driven generator sets (or gensets) for energy to power the mill. And as a bonus, the waste heat from the generators will be fed back into the mill to dry pulp. Slave Lake Pulp is the first in the forestry industry to recover exhaust heat and use it in this way.

Alberta organizations such as the Climate Change and Emissions Management Corporation (CCEMC) provide funding for projects that reduce greenhouse gas emissions that are “new and novel” – meaning that the project is original and innovative to the industry. At Slave Lake Pulp, a 120,000 cubic meter tank was built last year to serve as anaerobic fermenter which will take waste water from the mill and digest it into methane gas. The gas will be cleaned and then burned in the engine driven generator sets (or gensets) for energy to power the mill. And as a bonus, the waste heat from the generators will be fed back into the mill to dry pulp. Slave Lake Pulp is the first in the forestry industry to recover exhaust heat and use it in this way.

The anaerobic bulk-volume fermenter

Many pulp mills have similar energy generation projects underway; for example, some mills collect bark – a not-so-useful byproduct – and burn it for energy and heat. The forestry industry as a whole is shifting towards carbon neutrality and producing clean energy as it does so.