Log Quality Audits

August 4, 2020 11:50 am Leave your thoughts

For my fourth post, I would like to share my experiences performing log quality audits throughout the month of July and continuing into August.

When I accepted the position of Forest Operations Intern at Weyerhaeuser Grande Prairie, I expected to be spending much more time in active harvest blocks. It is part of the reason I was so eager to accept the job. That being said, the duties I have taken on have been wonderful learning experiences, and I do not doubt that they will have a positive impact on my career moving forward. Needless to say, finding myself on a cut block mid-harvest had me very excited to learn about how things work in our forest management area.

My background in harvesting comes from a few years of operating a slasher in the hardwood forests in central Ontario. A slasher is a large piece of forestry equipment that handles full length stems, bucks them down to appropriate size and sorts them accordingly to be loaded by log trucks. The standing timbre is felled in the forest by a feller buncher, typically delimbed manually by a chainsaw and skidded to roadside by a grapple skidder. This is different than the clear-cut systems that happen in Northern Ontario where I attend University and here in Grande Prairie, where I am employed for the summer of 2020. In a clear-cut system, a typical harvest consists of a feller buncher, a skidder, a delimber and a processor. In many circumstances, the processor is equipped with delimbing capabilities, which helps in cost savings.

A skidder mounted slasher (Les Enterprises LRJ).

A big reason why these systems are approached differently is simply the species of wood involved and the landscape those species occupy. Hardwood species like sugar maple, yellow birch and oak are dense and heavier to manage, and therefore require different machine capabilities. Dense and large diameter wood is much easier to cut with a large circular saw that is found on a slasher. Processors found in clear cuts often buck the wood to length using chainsaw bars that are built into the processing head of the machine. Another important factor to consider is the way these two different types of forests are managed. Sugar maple are a shade tolerant species, which means that young saplings thrive in a dense canopy. With that in mind, foresters can approach a harvest stand by utilizing the selection method of harvesting. In a nutshell, the goal is to remove trees to emulate single tree mortality which opens the canopy in a slight and controlled fashion, freeing the young sapling below. Clear cut systems aim to emulate natural disturbance patterns, such as fire, that have been controlling the landscape for thousands of years and target softwood species like black spruce and jack pine.

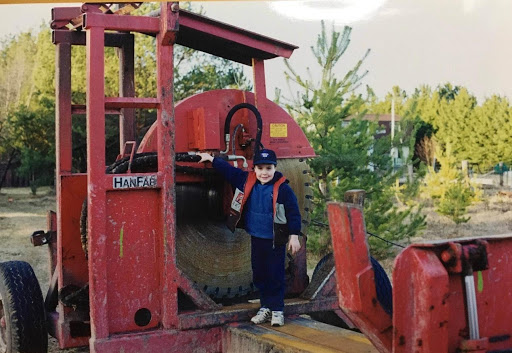

Yours truly, standing next to the blade of a slasher.

Something that spans all harvesting operations is the importance of log quality and stem utilization. Depending on the quality specifications required by the mill and their ability to take specific lengths and diameters of processed wood, foresters managing harvest contractors must keep an open dialogue about the importance of stem utilization with their operators. In Weyerhaeusers case, each contractor is subject to a weekly quality inspection of no less than 50 saw timber grade logs. This is a great opportunity for the ops foresters to be in the block with the contractors and operators to help them calibrate stem quality and utilization.

Log quality audits are completed with the use of a measuring tape and a thorough understanding of what the specifications are from the mill. If the mill can only take timber of log or pulp quality up to a certain diameter or length, it is up to the operators on site to process the timber accordingly and for the operational forester managing the area to discuss any issues with them on site. The mill, and their requirements, can change over time to increase stem utilization. An example of this is the amount of rot allowable in a stem. In years prior, mills were asking for nearly perfect log quality. No allowable sweeps, crooks, or defects. In recent years however, the importance of utilization has become an area that many mills and timber companies have focused on improving. Lowering the threshold on what constitutes a log allows the mill to push for boards in logs that would have previously been sent to the pulp mill. Obviously, the bigger and better the log is, the more boards that can come from it, but acceptance of smaller and less favourable wood is allowing mills to adapt and become more sustainable.

Lumber pile in an active harvest block.

The goal is to achieve the maximum amount of saw timber from the forest while minimizing the amount of pulp. Ultimately, an operator should be able to identify and extract varying quality and size of saw timber from their unprocessed piles and avoid leaving waste by utilizing undesired wood into pulp lengths and specs. The processing of timber is achieved by both skill acquired over time by the operator, as well as with the aid of technology within the machine itself. Computers within the machine are used to help measure diameter and length of timber, which logs all data instantaneously, providing the operator and forester alike, the advantage of tracking volume cut per hour, day and week. This is a technology not available on the machines that I operated, when we based our volumes from the weight scales at the mill, and less officially, how many truck loads would be hauled out as we slashed. Weight scales are still used throughout the industry at mills but having real time data in the hands of the operators, contractors and ops foresters is a valuable asset.

Log Quality Training

The reason it took until mid-July to find myself in an active harvest is due to weather events in the previous seasons. Grande Prairie experienced a significant amount of rainfall in the summer of 2019, and coupled with the levels of snow this past winter, there has been an increase in ground saturation that has limited which zones of the Forest Management Area can be harvested over the summer. In a normal harvest season, the goal is to be harvesting as soon as ground conditions permit in the spring. This has not been the case for our area in the summer of 2020, as operations were held off until late June/early July. Weyerhaeuser has had to work around these unfortunate weather events by relying on more winter harvest blocks. Winter harvest typically takes place in areas that are more saturated and will be harder to harvest in the summer without causing rutting damage to the landscape as heavy equipment and trucks traverse blocks. Winter harvest can be more cost effective, as less work is needed to put in a road and maintenance costs are lessened. Understanding the landscape from a planning perspective is needed to decide what is or is not a winter harvest block. Walking cutblocks with different operational foresters over the summer has shown me the importance of understory vegetation identification and understanding what different soil types mean. A quick scan of an area, along with digging up a small patch of earth and running it through your hand can be very telling if the block should be considered for a winter harvest. When planning harvests, it is equally as important to calculate if the designated blocks can sustain the number of contractors hired on. The goal here is to appropriately utilize the operators and the landscape, and to minimize gaps in the wood supply to the mill.

Of the duties assigned to me this summer, log quality audits are near the top of the list in terms of interest. It likely comes from my background in harvesting and spending so much time focusing on log quality when working with the family business. I thoroughly enjoy learning the differences between log qualities in different species and learning what different mills require and why. Earlier in the summer, discussions of a mill tour were discussed, something that interested me very much. Seeing the logs from the vantage of the workers in the mill puts log quality on the block into a much clearer perspective. Unfortunately, due to the current restrictions and dangers associated with the COVID-19 pandemic, it is likely a mill tour will not occur.